Production Planning is the heart of any manufacturing industry, it ensures all necessary preparation is done before the production cycle begins. Imagine you started cooking and you miss an important ingredient, or you are hosting a party, and you don’t know how much food you need to prepare. Not ideal, right? You can only do it well if you know exactly what you need, how much you need and you have all the tools and resources available with a perfect recipe for it. Otherwise, it can be a nightmare.

It becomes critically important to optimize production planning when you are dealing with high volume and high-cost products. Optimizing production planning leads to minimizing the raw material, storage, setup, operation costs and enhance production efficiency and hence maximizing the profits.

Demand forecast as per unpredictable market requirements, over stock and stockouts, capacity limitations, material shortages, supply chain and logistics are the main challenges faced by manufacturers to optimize the production planning.

Addressing these challenges often requires a combination of advanced planning tools, effective communication, robust processes, and continual improvement practices along with the adaptability to the fast-changing technological developments. As the business grows, managing and analyzing large volumes of data from different sources can be challenging as well.

Thanks to some ERPs who are ever evolving to address these challenges. Let’s see what SAP PP has in store to future-proof production planning for your industry.

Trends and innovations shaping the future of SAP PP

Here’s a look at some key innovations shaping the future of SAP PP:

SAP Fiori: Fiori apps are designed to simplify tasks, improve productivity, and offer more intuitive and user-friendly interfaces with consistent experiences across devices. Customizable and personalized dashboards are becoming a norm, allowing users to access relevant information and KPIs tailored to their specific roles and responsibilities and hence make better decisions. Cloud-based solutions, like SAP S/4HANA Cloud, are transforming SAP PP by providing real-time data processing, scalability, and flexibility. Cloud-based systems facilitate easier integration with other cloud applications and services, enabling more agile and responsive production planning. Hybrid Cloud Environments are also an option. This approach allows for greater flexibility and scalability in managing production planning processes.

Integration with Advanced Technologies like Artificial Intelligence (AI) and Machine Learning (ML) are enhancing SAP PP by enabling predictive analytics for demand forecasting, optimizing production schedules, and identifying potential disruptions before they impact operations. These technologies help in automating decision-making processes and improving the accuracy of production planning.

IoT Devices and Sensors are Being Integrated into SAP PP to provide real-time data on equipment performance, inventory levels, and production processes. Real-Time Analytics: Advanced analytics tools are being integrated with SAP PP to provide real-time insights into production performance, inventory levels, and supply chain dynamics. This capability allows organizations to make data-driven decisions and respond quickly to changing conditions. SAP PP is leveraging big data technologies to gain deeper insights into production processes and optimize planning strategies.

Integrated Supply Chain Collaboration and Demand-Driven MRP (DDMRP): SAP PP is enhancing its capabilities for collaborative planning across the supply chain. Improved integration with suppliers, customers, and other stakeholders enables more agile and responsive production planning. Demand-Driven MRP (DDMRP) is gaining traction as a method to improve material requirements planning by focusing on actual demand and inventory levels rather than traditional forecasts.

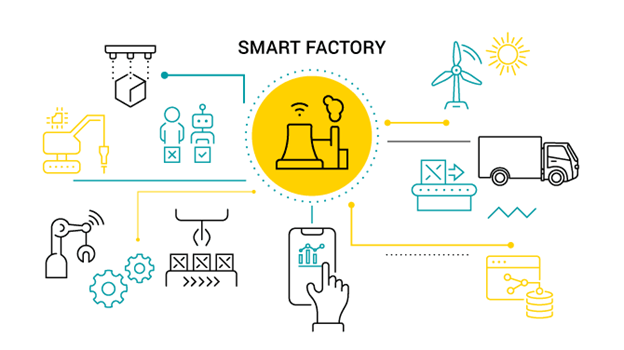

Smart Factories: The concept of smart factories, where production processes are highly automated and interconnected, is influencing SAP PP. Integration with Industry 4.0 technologies enables real-time monitoring and control of production processes, leading to more efficient planning and execution.

How to prepare your SAP PP system for upcoming technological advancements

Preparing your SAP Production Planning (PP) system for upcoming technological advancements involves several strategic steps. The challenge is to enhance its capabilities without disturbing the operational efficiency. Here’s a guide on how to prepare your SAP PP system:

Evaluate Current System Capabilities and Bottlenecks: Conduct a thorough assessment of your current SAP PP system to identify its strengths, limitations, and areas that need improvement. Perform a gap analysis to understand how your current system aligns with emerging technologies and industry trends. A good idea is to find the pain points and address the issues with the latest available solution with SAP PP. Identify gaps that need to be addressed first to leverage new advancements effectively.

Upgrade to SAP S/4HANA: If you haven’t already, consider migrating to SAP S/4HANA. The S/4HANA suite offers significant advancements in performance, real-time analytics, and user experience. Prepare for cloud-based solutions by integrating SAP PP with SAP S/4HANA Cloud or other cloud services. This enables scalability, flexibility, and real-time data access. Leverage APIs and integration tools to connect SAP PP with other enterprise systems, IoT devices, and third-party applications. This ensures seamless data flow and improved process automation. Your team will need to be trained on new features and technologies being introduced to SAP PP. The upgrade or migration to S/4HANA also gives an opportunity to cleanse the data, remove obsolete entries and establish data governance practices to manage data integrity, security, and compliance. This includes defining data ownership, access controls, and data management policies. High-quality data is crucial for leveraging advanced technologies effectively.

Implement Advanced Analytics and Reporting: Incorporate real-time analytics capabilities to monitor and optimize production processes. Utilize SAP Fiori and SAP Analytics Cloud for advanced reporting and dashboard capabilities. Implement predictive analytics to forecast demand, identify potential issues, and make data-driven decisions. AI and machine learning can enhance these capabilities by providing more accurate insights.

IoT and Automation: Integrate IoT devices and sensors with your SAP PP system to collect real-time data on production processes, equipment status, and inventory levels. This data can enhance decision-making and process optimization. Explore opportunities for automating routine tasks and processes within SAP PP. Automation can reduce manual intervention, increase accuracy, and improve overall efficiency.

Adopt a Phased Approach: Develop a clear roadmap for adopting new technologies and integrating them into your SAP PP system. This includes setting priorities, timelines, and resource requirements. Implement changes in phases to minimize disruptions and ensure smooth transitions. Testing new functionalities and integrations thoroughly before full-scale deployment is important for a successful transition.

Collaborate with SAP Partners and Experts: Engage with SAP consulting services or partners who have expertise in SAP PP and emerging technologies. They can provide valuable insights, guidance, and support for your transition.

Preparing your SAP PP system for upcoming technological advancements requires a proactive and strategic approach. By evaluating your current system, staying informed about trends, upgrading to SAP S/4HANA, enhancing integration, investing in training, and focusing on data quality, you can position your SAP PP system to effectively leverage new technologies and drive operational excellence. Collaborating with experts and adopting a phased implementation approach will help ensure a successful transition and maximize the benefits of technological advancements.

ORBIS Solutions for SAP PP

SAP S/4HANA Migration

Digitalization made easy with SAP S/4HANA by ORBIS with their S/4HANA Cloud, Rollout or Transformation Projects.

ORBIS MES and Smart Factory Solutions

For digitalizing production, ORBIS MES is the solution that’s fully integrated into SAP S/4HANA or SAP ERP (SAP Enterprise Resource Planning) system to orchestrate and automate processes between the shop floor and the MES and SAP systems / applications.

ORBIS Analytics MES Dashboard

You can keep track of all your KPIs – graphically displayed, clear and interactive. The ORBIS Analytics MES Dashboard is part of the ORBIS Best Practice solution for MES Reporting. Whether you use an ORBIS MES or a different MES.