Manual actual data collection and PPM target value planning with SAP BW IP and SAP Design Studio in Quality

Sectors: Automotive supplier industry

Processes: Quality Management, Service & Support, Analytics

References: ZF

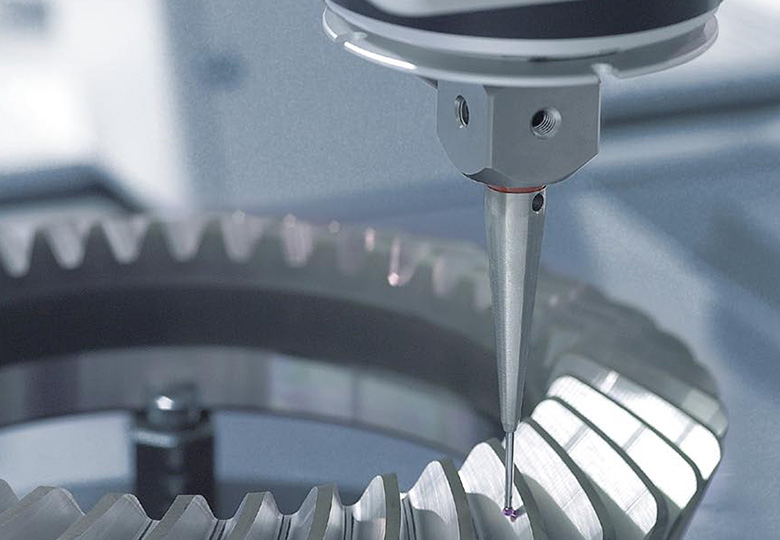

Name: ZF Friedrichshafen AG

Employees: around 135,000

Products: World’s leading technology group in drive and chassis technology, as well as in active and passive safety technology

Head office: Friedrichshafen, Baden-Württemberg

Sites: 230 sites worldwide

Originally, ZF Friedrichshafen AG evaluated various reports from the Quality Department using Excel reports. But because this process required a great deal of manual effort, it went on the search for automated and standardized solutions to simplify and improve reporting. In addition to reporting, existing actual data was to be used as a basis for planning future values for the “Deliveries” and “Fai- lures” key performance indicators and the ratio calculated from them in parts per million as “PPM target values”.

SAP BW offers ideal conditions for implementing reporting and planning. All the required data is located centrally in a logical system. Master and transaction data can be harmonized, and SAP standard tools and services – such as Integrated Planning (SAP BW IP) – can be used.

Source Photo: © ZF Friedrichshafen AG

ORBIS supported ZF in setting up the actual reference data in SAP BW and designed a web-based planning interface for recording the target values.

Providing the actual data required two differentiated approaches. For “SAP plants” that use an SAP ERP system, the data can be loaded into BW using extractors from the source systems. For “non-SAP plants” that did not previously keep data in a system, ORBIS set up a maintenance screen on the web that enables manual entry of actual data. During this process, users could work with BW IP resources, which are also used to implement planning solutions. SAP Design Studio was used as the front end. The central requirements of a Copy & Paste function, which allows data to be lifted from external files and pasted into the maintenance screen, as well as the opportunity to add comments, could be mapped in full.

For target value entry, ORBIS built a web-based maintenance screen using SAP Design Studio and the help of BW IP resources. Future PPM target values are now planned and calculated based on the actual data provided by SAP and non-SAP plants.

An Administrator Cockpit is used to control the planning process. It can be used for the likes of maintaining application-specific, harmonized master data. General parameters – such as the current planning year – can be set, or global planning functions – such as copying versions – can be executed. The data is reported by the process administrators themselves; IT has a supporting role in this regard.

Source Photo: © ZF Friedrichshafen AG

Backend: SAP BW, BW-IP

Frontend: SAP Design Studio, BO Launchpad