ORBIS Manufacturing Execution System (ORBIS MES)

What are Manufacturing Execution Systems?

Manufacturing Execution Systems (MES) are used in manufacturing to track and document the transformation of raw materials to finished goods on the shop floor. They eliminate human error and paper-based systems through manufacturing process automation and thus, provide real-time data collection in your ERP system. In short, Manufacturing Execution Systems are designed to optimize shop floor production processes and give you complete control over your manufacturing operations in real-time.

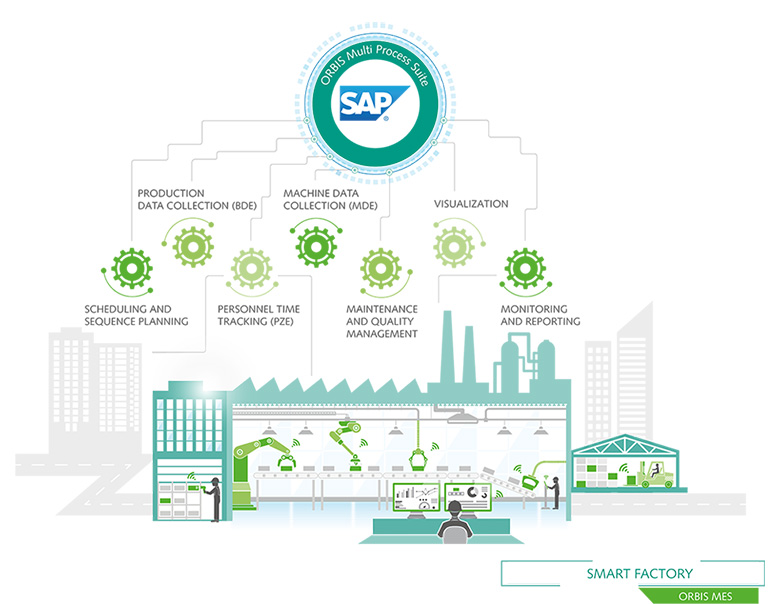

Fully integrated SAP ERP solution for digitalizing production

ORBIS has developed its own Manufacturing Execution System: the ORBIS MES Solution. It is designed based on the ORBIS Multi-Process Suite (ORBIS MPS) and SAP Business Suite. In fact, it is 100% integrated into SAP ERP and is therefore the central building block for efficient integrating and synchronization of data from the shop floor with SAP processes and for the establishment of a digitally networked value chain.

Machines, devices, sensors, and actuators can communicate with SAP ERP and its processes, using ORBIS MES. ORBIS Manufacturing Execution System enhances the SAP ERP by providing a virtual representation of shop floor events in real-time and facilitates end-to-end planning and controlling of the digital factory in the SAP system. ORBIS MES is compatible with both SAP ECC and S/4 HANA.

Core Functions:

- Real-time visibility and traceability across manufacturing supply chain

- Allows manufacturers to make informed operational decisions based on up-to-date information readily accessible in your ERP system

- Management dashboards for production control and monitoring

- Seamless integration of end devices with your Enterprise Resource Planning (ERP) system

- User-friendly and industry-standard user interfaces for the visualization of production processes

Why use ORBIS MES?

- Seamless integration with SAP ERP, SAP HCM, SAP BW

- Can be realized exclusively using SAP development tools

- Keep up with Industry 4.0 initiatives

- Residue-free scheduling and sequence planning with the ORBIS planning tool

- Modular structure of the MES with functions for Machine Data Collection, Plant Data Collection, Plant Maintenance and Quality Management, among others

- Simple expansion concept for the realization of customer-specific requirements

Integrate digital factory shop floor with SAP ERP

Modules of ORBIS MES

Machine Data Collection

"Real-time" view of machine and system states and effective control of all production processes.

Monitoring and reporting

Transparency in production - exactly informed at all times and everywhere

Scheduling and sequence planning

Backlog-free planning of each individual production area and long-term increase in transparency in the order and schedule structure with the ORBIS planning tool.

Production Data Collection

Real-time view of all operating data and control of all production processes. Complete transparency as a basis for permanent optimization and objective cost control.

Personnel Time Tracking

Simplified and effort-reduced personnel time recording - easy to operate and clear interfaces

Maintenance and Quality Management

More efficiency and cost reduction - optimized downtimes and fault management, preventive maintenance, organization of machine data, measurement and test results.

Visualization

High-performance and industry-standard user interfaces - platform-independent and on all common end devices.

MES Plug & Play: Choose the right box & get started

ORBIS Shop Floor Boxes

Do not lose any time or resources in the digitalization of your production and logistics!

"Out of the box" immediately ready to use with a short implementation time and a clearly defined cost framework, our ORBIS Shop Floor Boxes in sizes S, M and L offer you exactly what you need to digitalize your shop floor.

More about ORBIS Smart Factory

Smart Factory by ORBIS

Continuous process automation and "real-time" networking of all actors in the digital factory - 100% integrated in SAP.